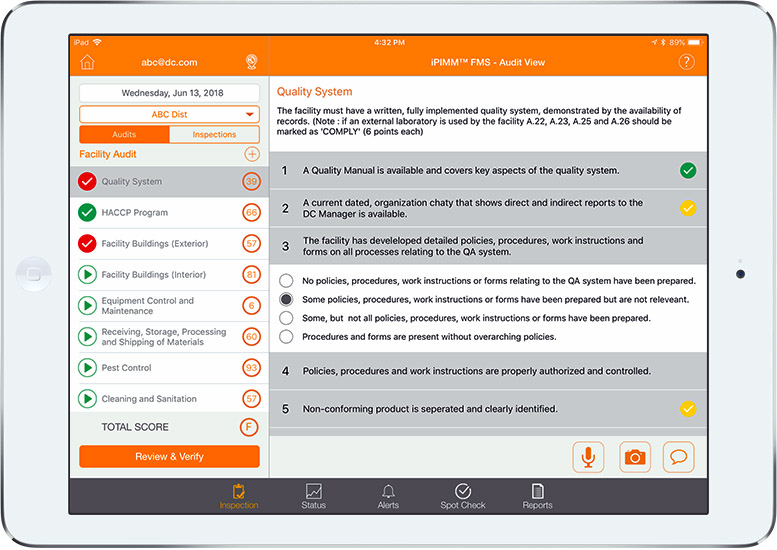

Audits & Inspections

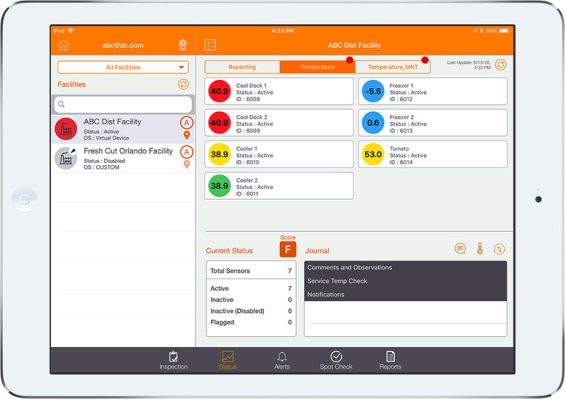

PIMM™ FMS provides centralized management of zones, thresholds, inspection criteria and corrective action procedures for each cold storage facility.

Each facility receives a “Quality Grade” that can be shared with customers to verify proper cold chain management processes and procedures.

Building Mgmt. Services

Managing components is the key to lowering operational costs. PIMM™ FMS manages compressors, condensers, evaporators, fans, etc.

Managing the components is providing root cause detection.

The PIMM™ AI (Artificial Intelligence) engine maps the inter-dependencies within a building to quickly identify the root cause and initiate bi-directional corrective actions to avoid potential problems and/or outages.

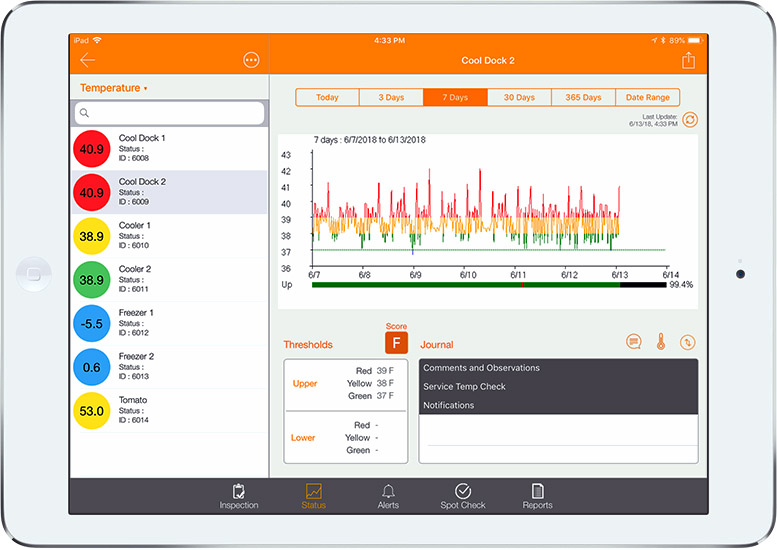

Thresholds & Alerts

PIMM™ FMS provides centralized management of zones, thresholds, inspection criteria and corrective action procedures for each cold storage facility.

Each facility receives a “Quality Grade” that can be shared with customers to verify proper cold chain management processes and procedures.

Preventative & Predictive Maintenance

The future of PIMM™ AI being applied more and more to “Predictive Management” solutions. Building Management Systems is a great example of where AI can significantly enhance the operational efficiency of systems like HVAC; Lighting; Energy Mgmt.; Security; Power Systems; Gears, Sub-Feeds; 24-hr Standby; etc.

The critical factor is the inclusion of “Meantime to Failure” estimates for each component. These estimates could be based upon a time; cycles; operating hours; environmental conditions; etc. The PIMM™ AI engine will be able to predict failures and dramatically enhance the Reliability, Availability & Serviceability (RAS) of each and every facility.

The PIMM™ AI will combine the data from the Asset Profile with the “Usage” data from the operation of the component and/or equipment to properly assess the current status against the projected “meantime to failure”.

PIMM™ will dynamically create a “Preventive Maintenance Alert” when the threshold of the component or equipment is violated. The corrective action could be a reset or a restart; a required lubrication or calibration; an automatic re-order of a replacement part; etc.

The key is to act before the incident or event.

The PIMM™ AI engine will:

- “Predict” a problem

- Issue the “Preventive Maintenance Alert”

- Create the “Corrective Action”; and

- “Order” the work order or required parts; then

- “Confirm” that the Corrective Action was implemented

The goal is to Prevent Incidents and Events and allow the Ops team to Sleep Well!!